Norsok S-002, v4, Working environment, specify use of WEAC.

The NORSOK standards are developed by the Norwegian petroleum industry to ensure adequate safety, value adding and cost effectiveness for petroleum industry developments and operations.

Norsok S-002 apply to the design of new installations and modification or upgrading of existing installations for offshore drilling, production, and utilisation and pipeline transportation of petroleum, including accommodation units for such activities.

The main purpose of the WEACs is to include the results of predictions and verification measurements (e.g. as-built data for illuminance and noise), and describe identified problem areas and nonconformities as well as the status regarding decisions on remedial actions.

Although S-002 is made for newbuilds and modifications, the specifications in the standard are commonly used also in operations. This also include using WEACs to document status of the individual areas.

A bachelor thesis in 2009 by Lars Jensen and Helge Nesse listed the following experiences:

Other user experiences have been:

Since 2012 the Norwegian Petroleum Safety Authorities have kept a focus on use of WEAC for the area documentation.

With this background the company WE sustain released an online WEAC database in 2008. Following increased focus from the Petroleum Safety Authorities on documentation of risk of risk exposed groups and risking of each element and the summed up risk, this database was updated in 2012 to support exposure and risk on work groups.

Adding much functionality to the software made it complex and the user friendliness suffered. In order to ensure easy access of working environment information for first line managers and workforce, the software had a total rebuild and was released as WElix in 2017.

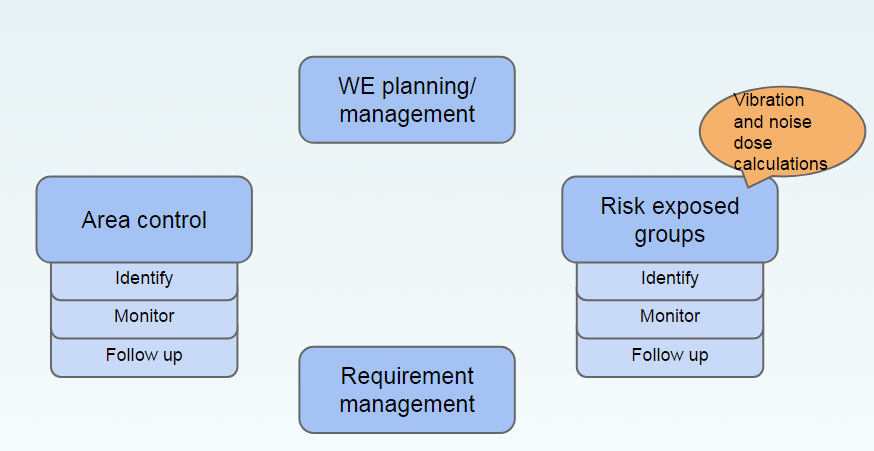

With a basis in WEAC, location based status, WElix has addressed the original challenges with WEAC and attempts to provide user friendly support to manage occupational risk as a whole. The information imported to the system is used to generate new results, such as Noise exposure per job and KPIs in addition to status overviews per job and per location. As such the software supports the activities listed in ISO 45001.

Meant to support the management in complying to their responsibilities, ensuring they have control on any yellow and red occupational hazards, the software does not require any training for users of the data. Even so HSE staff need to champion the system, ensuring risk assessments are consistent and at an acceptable quality.

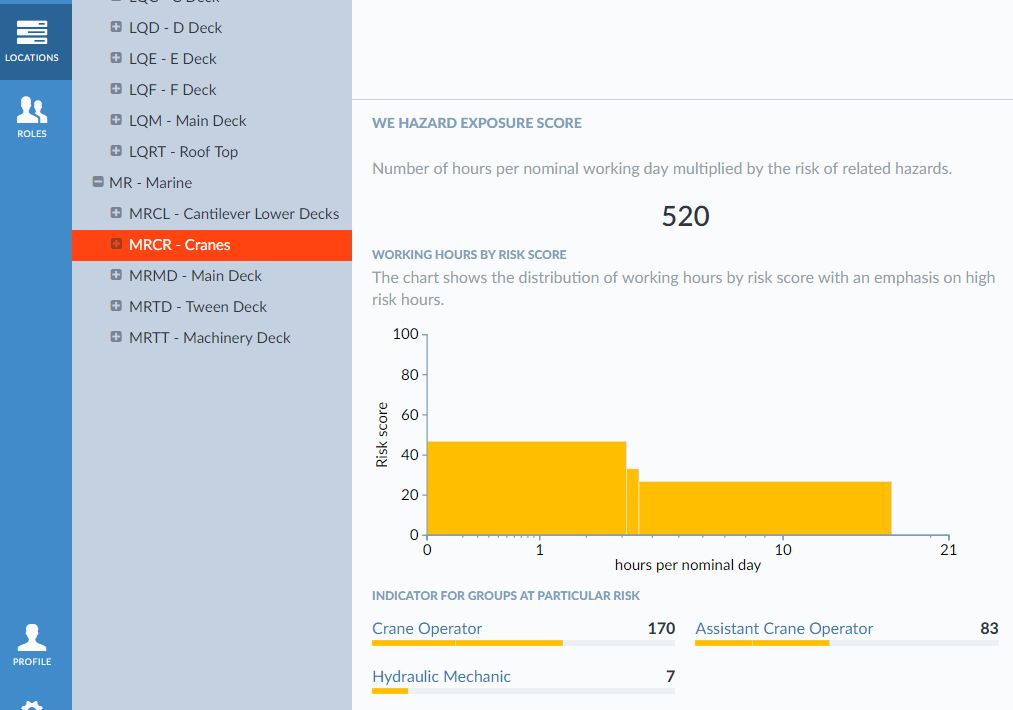

One of the interesting new functionalities in WElix is the KPI called Working Environment Hazard Exposure Score (WEHES). It combines the risk rating of a particular WE hazard with the exposed man hours.

The KPIs can be viewed for any given workplace, area, or even for any task or job. All open WE hazards can be sorted and prioritized by WEHES. This gives support to priorities and management processes.

Feedback from existing users of the old version software has been used in the programming of WElix. An odd example is reports from users that they occasionally lost registered data when the internet went down offshore. In the browser based WElix the data is temporarily saved on the PC, to avoid such experiences.

The software has been made for offshore use. Simplifications are in process, making it cheaper and easier to configure and use for other industries.